Inside Tesla’s Octovalve

Tesla’s latest electric vehicles employ one of the most sophisticated cabin HVAC and heat pump systems in the auto industry. At its core is the Octovalve – an eight-port thermal manifold that intelligently routes coolant and refrigerant to manage the cabin climate, battery temperature, and powertrain cooling in unison. This article dives deep into the engineering of Tesla’s heat pump and Octovalve system, how it integrates cabin and battery thermal management, the efficiency gains it achieves (especially in cold climates), the materials and components that make it work, and how it compares to conventional and competitor EV HVAC designs.

Octovalve System Design and Operation

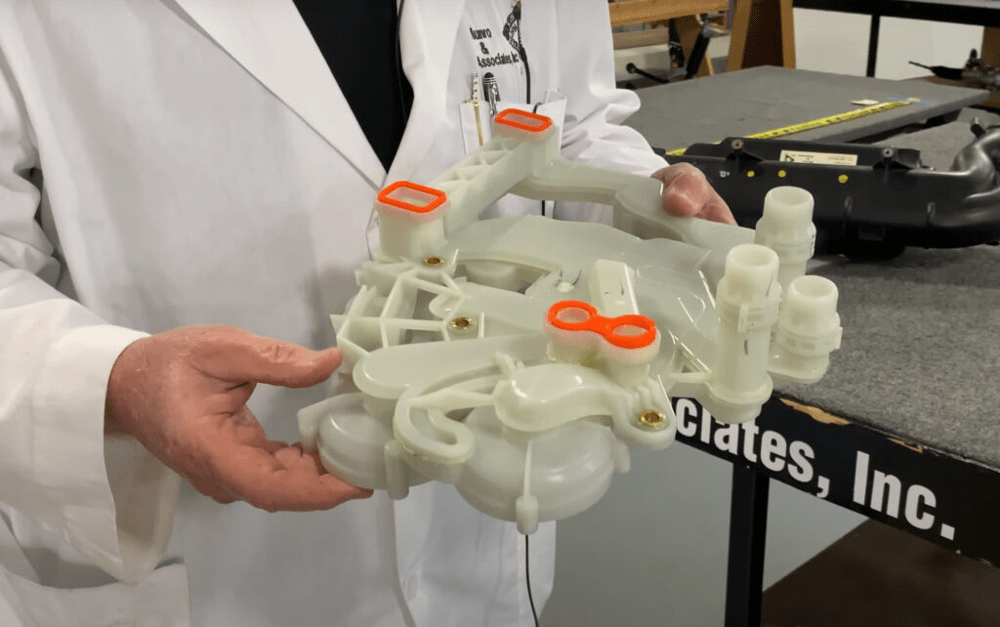

(Inside Tesla’s Octovalve – VASA) Figure: Munro & Associates holding the Model Y’s multi-port coolant manifold (the Octovalve’s orange-ringed ports interface with this manifold). The Octovalve assembly integrates numerous cooling/heating functions into a single unit.

Tesla’s Octovalve is an innovative rotary valve with eight ports that replaces a tangle of separate coolant valves and loops. Housed in a compact unit about the size of a briefcase at the front of the vehicle, it directs the flow of coolant through various components that need heating or cooling (Tesla Octovalve analysis – E-Mobility Engineering) (Inside Tesla’s Octovalve – VASA). An electric stepper motor rotates the internal disk (up to ~270°) to switch between five discrete flow configurations, effectively acting as multiple valves in one (Tesla Octovalve analysis – E-Mobility Engineering). This single device can route coolant to the cabin heater core, battery chiller, drive unit coolers, and other loops as needed, hence the “octo” name for its eight channels.

The Octovalve is paired with two integrated manifolds in Tesla’s heat pump system (Tesla Octovalve analysis – E-Mobility Engineering). One is a polymer coolant manifold (molded nylon) that the Octovalve attaches to, and the other is an aluminum “super-manifold” for refrigerant (Tesla Octovalve analysis – E-Mobility Engineering). Sandwiched together, these manifolds consolidate what would traditionally be a maze of hoses, valves, and fittings. In the Model Y teardown, Munro & Associates noted the refrigerant super-manifold is composed of only three main parts (a brazed plate, a forging, and an extrusion forming the chiller) – versus hundreds of parts in conventional designs like those in the Chevy Bolt or Nissan Leaf (Tesla Octovalve analysis – E-Mobility Engineering). This integration eliminates many potential leak points and improves reliability (Tesla Octovalve analysis – E-Mobility Engineering).

Key components of the heat pump system are mounted to these manifolds, including a high-efficiency electric compressor, an expansive chiller (a coolant-to-refrigerant heat exchanger), and a liquid-cooled condenser (Tesla Octovalve analysis – E-Mobility Engineering) (Inside Tesla’s Octovalve – VASA). The compressor circulates R1234yf refrigerant through the system, and depending on the Octovalve position, this refrigerant can either absorb heat (evaporate) or release heat (condense) in different areas. For example, in AC mode it will chill coolant via the chiller or cool the cabin evaporator; in heating mode it can condense in the cabin heater core or in a battery loop heat exchanger. Tesla’s design thus acts as a “thermal traffic director,” switching the refrigerant flow path and coolant routing to where heat needs to be added or removed.

Crucially, Tesla’s HVAC unit still includes conventional elements: a front radiator (for shedding heat to outside air when needed), a cabin evaporator and condenser coil (within the HVAC airbox for cooling or heating the cabin air), expansion valves, an accumulator, and even a small auxiliary cabin heater (Tesla Octovalve analysis – E-Mobility Engineering). But unlike legacy systems, all these are tied together by the Octovalve and manifolds into one cohesive circuit. The result is a dramatically simplified hardware architecture – far fewer hoses and parts – enabling tighter control. Munro’s analysis praises this as “genius,” noting how a multitude of functions were consolidated into one device (Inside Tesla’s Octovalve – VASA). In Elon Musk’s own words, the new heat pump has a “local heating loop” that can spin up and get hot internally before blending into the main loop, improving efficiency at low temperatures (Tesla’s Octovalve Enabled A Staggering 10% Increase In Range For The Model Y – CleanTechnica). This reflects the Octovalve’s ability to internally recirculate and condition coolant before opening flows to the cabin or battery.

Overall, the Octovalve system is the “brain” of Tesla’s thermal management. By rotating to different positions, it can configure the coolant loops into various topologies (Tesla’s patent describes 15 modes in total (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media)). This clever engineering allows one heat pump to serve multiple thermal needs throughout the car – something rarely seen in traditional automotive HVAC. It is an elegant hardware solution to manage complex thermodynamic cycles with minimal components.

Integrated Cabin, Battery, and Powertrain Thermal Management

One of the Octovalve heat pump’s biggest advantages is how it balances the thermal needs of the cabin and the electric powertrain dynamically. In a Tesla, the cabin heating/cooling, battery temperature control, and drive unit cooling are not separate silos – they are highly integrated and share heat/cold as needed. This is achieved through active flow control (via the Octovalve and refrigerant valves) and intelligent scavenging of heat.

Tesla’s system constantly monitors temperatures throughout the vehicle: cabin air temperature, battery pack temperature, motor/inverter temperatures, ambient outside temp, and even the temperature of coolant at various points. Using these inputs, the vehicle’s thermal controller can decide on an optimal mode. Some examples of how the system operates in real-world scenarios:

- Normal cabin heating (mild cold, above ~ -10 °C): The heat pump draws heat from outside air and any available waste heat. In this mode, refrigerant might evaporate in the front radiator acting as a heat collector, then get compressed. The hot refrigerant is routed to the cabin heater core (condenser) to warm the air (Inside Tesla’s Octovalve – VASA). Additionally, the Octovalve can direct warm coolant from the motor/inverter loop or battery (if they are warm) into the cabin loop. In Tesla’s patent “Mode 9,” the Model Y can actually heat the cabin using three sources at once – ambient air, the battery pack, and the drive unit – maximizing efficiency (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). Using higher-temperature sources (battery and powertrain) improves heat pump COP, akin to a geothermal heat pump drawing from a warm ground source (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media).

- Extreme cold cabin heating (below ~ -10 °C): When ambient air is frigid and waste heat is minimal, Tesla employs creative strategies to maintain performance. The heat pump can reconfigure into a “COP=1” heating mode where the cabin evaporator and condenser are run simultaneously in a closed loop (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). This essentially turns the compressor into an electric heat source (like a dehumidifier running with the room door closed) – for every 1 kW of electricity in, ~1 kW of heat is delivered to the cabin (COP ~1). While this is no more efficient than a resistive heater, it allows the system to output ~5–6 kW of heat even when outdoor air yields no heat (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). In addition, Tesla supplements with 12V PTC heaters (small positive-temperature-coefficient electric heaters) for immediate warmth or windshield defrost (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). Tesla’s patent also describes running the drive motor inverter in an “off-phase” manner to intentionally generate waste heat in the motor, which the coolant can capture (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). These measures ensure that even at sub-freezing temperatures, the cabin can be kept warm and the battery within optimal temperature, albeit with reduced COP. As the patent notes, as you approach -10 °C and below, the system gradually adds these direct heating methods, causing COP to approach 1 (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). The brilliance is that all of this is managed automatically – the car seamlessly blends heat pump operation with auxiliary heating to optimize efficiency and comfort.

- Cabin cooling (hot weather): In summer, the system works like a conventional A/C but with extra tricks. The heat pump (acting as an A/C) absorbs heat from the cabin via the evaporator and can reject that heat to the outside radiator. But if another part of the car needs heat, Tesla can redirect some of this thermal energy instead of wasting it. For instance, if the battery is too cold (e.g. during initial fast charging on a cold day, or in a rare case of cabin overheating while battery is cool), the heat from the cabin can be pumped into the battery to warm it (Inside Tesla’s Octovalve – VASA). More commonly, during cabin cooling the refrigerant flow can be arranged so that the battery coolant loop is cooled via the chiller in parallel – effectively cooling the battery and cabin together with one system. Tesla prioritizes critical components; for example, the powerful Autopilot/ADAS computer gets the coldest coolant first, right after the chiller, to keep electronics at safe temperatures (Tesla Octovalve analysis – E-Mobility Engineering). All excess heat can be dumped to the front radiator which has active shutters to close off airflow when not needed (reducing drag) (Inside Tesla’s Octovalve – VASA).

- Battery preconditioning and thermal storage: Tesla leverages this integrated system to actively manage the battery’s temperature for performance and longevity. Before fast charging (Supercharging), the system will heat up the battery pack to the optimal temperature for charging. In older models this was done by drawing resistive heat or inverter-generated heat from the drive units; with the Octovalve heat pump, the car can more efficiently pump heat into the battery loop. Interestingly, the system can also do the reverse – store heat in the battery pack. If the car is parked on a sunny winter day, the cabin might passively warm up from solar gain. Tesla’s patent describes a mode where that cabin heat is absorbed by the heat pump and pumped into the battery, using the battery’s large thermal mass as a heat reservoir (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). The pack can later release that stored heat to warm the cabin after the sun goes down. By allowing the pack temperature to swing between, say, 10–25 °C, as much as 2.5–3 kWh of thermal energy can be banked in the battery (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). This kind of synergy – using the battery as a thermal capacitor – is unique to EVs and Tesla has implemented it to reduce the need for drawing electrical energy to heat the cabin.

These examples illustrate how holistically Tesla’s HVAC is integrated. Instead of discrete subsystems (one for cabin, one for battery, etc.), there is a unified thermal network managed by the Octovalve. A multitude of temperature sensors feed into a centralized controller that decides, for instance, if excess motor heat should go to warming the cabin or if cabin cooling should be used to chill the battery, etc. The system can scavenge heat from anywhere it’s not needed and send it to where it is needed. As one analyst noted, it “allows heat to be drawn from any suitable source” by simply driving the pump and opening the right valves (Inside Tesla’s Octovalve – VASA). This is fundamentally different from a traditional car where, say, waste motor heat is simply vented if the cabin doesn’t need it, or an EV where a resistive heater wastes energy even while the motors run cool.

To summarize the key thermal management strategies Tesla employs:

- Multi-Source Heat Scavenging: The heat pump can draw from ambient air, powertrain electronics, and the battery to gather heat for the cabin (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). Waste heat is never truly “waste” in this system.

- Thermal Priority and Flow Control: Using the Octovalve, coolant flow is routed to critical components first (e.g. cooling the high-power computer or heating a cold battery) before less critical needs (Tesla Octovalve analysis – E-Mobility Engineering). This ensures safe operation while minimizing energy use.

- Active Heat Storage: The battery pack itself is used as a heat sink or source when advantageous, effectively storing thermal energy that can later be reused (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media).

- Cold-Weather Failsafes: In extreme cold, the system seamlessly shifts to direct heating – running the compressor in a closed-loop mode (COP ~1) and engaging small PTC heaters as needed (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media) (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). This guarantees cabin comfort even when heat pump efficiency plummets in subzero conditions.

- Waste Heat Boosting: By running motors/inverters in a deliberately lossy mode (drawing electrical current that produces heat but no torque), Tesla can generate additional heat on demand to assist the heat pump (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). Essentially, the drive unit can act as a heat generator when needed.

- One Radiator to Rule Them All: All cooling loops ultimately reject heat through a single front radiator assembly with computer-controlled louvers (Inside Tesla’s Octovalve – VASA). This consolidated design reduces aerodynamic drag and complexity, as opposed to having separate radiators for battery, motor, and AC condenser. The active grille shutters stay closed to retain heat when possible and open only when cooling is needed, improving warm-up times and efficiency.

The integration of these systems is what allows Tesla to intelligently juggle the thermal demands of cabin comfort and battery conditioning. In practice, a Tesla can warm the cabin without solely relying on battery energy, by harvesting drive unit heat, and conversely can cool the battery during fast charging by using the AC system – all automatically. It’s a level of coordination akin to an orchestrated dance of fluids and refrigerant inside the car. Other manufacturers (notably Hyundai/Kia) have adopted similar multi-loop heat pump ideas, but Tesla’s Octovalve is a particularly elegant implementation that impressed independent engineers as “totally different from anything utilized by conventional OEMs” (Inside Tesla’s Octovalve – VASA) (Inside Tesla’s Octovalve – VASA).

Energy Efficiency Gains of Tesla’s Heat Pump

One of the primary reasons for Tesla’s switch from traditional resistive cabin heaters to a heat pump was to improve energy efficiency and extend driving range, especially in cold climates. Heat pumps can deliver significantly more heat per unit of electricity than a resistive heater – their effective coefficient of performance (COP) can be 2 to 3 or higher (meaning 1 kW of electrical power yields 2–3 kW of heat). Tesla’s system capitalizes on this, and also mitigates the typical weaknesses of heat pumps in the cold through the strategies discussed. The net result is a marked reduction in range loss in cold weather relative to older systems.

To quantify the gains, consider a comparison between Tesla models with and without the heat pump:

- Efficiency vs Resistive Heating: In one test at ~30 °F (-1 °C), a Tesla Model 3 (which in early models used a resistive heater) saw a 26% increase in energy consumption to heat the cabin, whereas a Model Y (with heat pump) saw only about an 8% increase under the same conditions (Study: How Much Heat Pumps Boost EV Range). In other words, the resistive-heated Model 3 needed roughly 3× more energy to heat the cabin than the heat-pump-equipped Model Y in near-freezing weather. This aligns with the COP ~3 advantage of the heat pump. Essentially, instead of drawing, say, 5–6 kW continuously for a resistive heater, the heat pump can heat the cabin with about 1.5–2 kW in those conditions.

- Range Retention in Winter: Real-world data aggregated by Recurrent Auto shows Tesla vehicles with heat pumps preserve a much larger fraction of their range in freezing temperatures than those without. For example, the heat-pump-equipped Model Y retains about 86% of its driving range in 0 °C conditions, whereas a comparable EV without a heat pump (like earlier Model S/X or other brands) might only retain ~65–70% (Here’s How Much Range These Popular EVs Lose In The Cold) (Here’s How Much Range These Popular EVs Lose In The Cold). Even within Tesla’s lineup, the introduction of the heat pump made a big difference – the new Model 3 with a heat pump retains ~87% range in the cold, versus ~79% for the previous Model 3 using resistive heat (Here’s How Much Range These Popular EVs Lose In The Cold) (Here’s How Much Range These Popular EVs Lose In The Cold). That is roughly a 10% absolute improvement in range retention. Notably, Elon Musk highlighted that the Model Y’s heat pump and Octovalve gave the larger Model Y an efficiency boost on par with the smaller Model 3, translating to a “staggering 10% improvement in efficiency” and enabling similar range (Tesla’s Octovalve Enabled A Staggering 10% Increase In Range For The Model Y – CleanTechnica). Independent winter tests corroborate these improvements: Volkswagen, for instance, claims that using a heat pump can increase range by up to 30% in extreme cold compared to resistive heating (Inside Tesla’s Octovalve – VASA). Tesla’s own gains fall in line, roughly on the order of 10–20% more real-world winter range due to the heat pump.

- Reduced Consumption per Hour: Traditional PTC cabin heaters in EVs draw a significant amount of power. The average EV HVAC needs on the order of 4–8 kW of heating capacity to warm the cabin and battery in winter (Study: How Much Heat Pumps Boost EV Range). A resistive system draws that 4–8 kW directly from the battery whenever heating is on, which can cut range quickly (up to ~40-50% range loss in very cold weather with heater running (Study: How Much Heat Pumps Boost EV Range)). By contrast, Tesla’s heat pump, with COP 3–4 in moderate cold, would draw only ~1/3 of that power for the same heat output (Study: How Much Heat Pumps Boost EV Range). Real-world usage bears this out. Owners who have monitored energy usage see that the heat pump typically draws on the order of 1–2 kW to maintain a warm cabin (once initial heating is done), whereas older resistive systems might draw 5 kW continuously in similar conditions. This is a massive efficiency gain. To put a number on it: running a 5 kW resistive heater for an hour consumes 5 kWh, which in a Tesla could be ~15–20 miles of range. The heat pump doing the same job might use 1.5 kWh – only ~5 miles of range. Over a long winter drive, that adds up to tens of miles of extra range preserved.

The table below summarizes a direct comparison between Tesla’s heat pump system and the previous resistive heating approach, highlighting the efficiency differences:

| Vehicle / Heating System | Cabin Heater Type | Approx. COP in Mild Cold | Observed Range Impact at 0 °C |

|---|---|---|---|

| Tesla Model Y (2020+, heat pump) | Heat Pump (Octovalve) | ~3 (300% efficient) (Study: How Much Heat Pumps Boost EV Range) | ~–8% range (~92% remaining) (Study: How Much Heat Pumps Boost EV Range) |

| Tesla Model 3 (2017–2020) | Resistive PTC Heater | 1.0 (100% efficient) (Study: How Much Heat Pumps Boost EV Range) | ~–26% range (~74% remaining) (Study: How Much Heat Pumps Boost EV Range) |

Table Notes: COP (coefficient of performance) is the ratio of heat output to electrical input. The resistive heater always has COP ≈1 (all input converts to heat), while the heat pump’s COP ~3 means it outputs ~3× the heat per kW. The range impact data above (from tests at ~30 °F) illustrates how the Model Y’s efficient heat pump preserved much more range than the older resistive system.

Looking at broader third-party data: In 2023, Recurrent analyzed thousands of EV data points and found Teslas with heat pumps were among the top performers in cold weather range retention (Here’s How Much Range These Popular EVs Lose In The Cold). For instance, the Model X and Model S (updated with heat pumps in 2021) retained ~88–89% of range at freezing, whereas some competitors without heat pumps were down near 60–70% (Here’s How Much Range These Popular EVs Lose In The Cold) (Here’s How Much Range These Popular EVs Lose In The Cold). This means a Tesla might only lose ~10–15% of its range in winter, versus 30–40% loss for an equivalent car without a heat pump. Even within the same model, as noted, the presence of a heat pump yields a noticeable jump in cold-weather efficiency (e.g., the Model S went from ~77% retention to 88% with the redesign) (Here’s How Much Range These Popular EVs Lose In The Cold) (Here’s How Much Range These Popular EVs Lose In The Cold).

It’s worth noting that heat pump efficiency does decline in extremely low temperatures – eventually negating the benefit. Tesla has pushed that boundary by keeping the heat pump running (with clever modes) well into subzero temps, but at –20 °C and below, even the best heat pumps have COP near 1. In those situations, Tesla’s system behaves like a resistive heater (drawing ~5–6 kW) by using the COP=1 compressor loop (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media) and auxiliary heaters. The advantage is that the same hardware seamlessly switches modes; there’s no efficiency penalty until you hit those extremes. And in typical winter conditions (0 to –10 °C), Tesla’s heat pump stays in high-COP mode for most of the time, yielding real savings. Owners in cold climates have reported that the newer heat-pump-equipped Teslas maintain range far better than older models – less need to charge as frequently or to worry about blasting the heater. In effect, Tesla has narrowed the gap between rated range and winter real-world range.

To further illustrate the cold-weather performance across vehicles, the following table compiles data on range loss in freezing conditions for Tesla’s models versus some competitors. It shows the percentage of range retained around 0 °C (32 °F) compared to temperate conditions:

| EV Model | Heat Pump? | Real-World Range Retained @ 0 °C (approx) |

|---|---|---|

| Tesla Model 3 (Heat Pump) | Yes | ~87% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| Tesla Model Y | Yes | ~86% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| Hyundai Ioniq 5 | Yes | ~85% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| Hyundai Kona Electric | Yes | ~84% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| Tesla Model 3 (Resistive) | No | ~79% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| Ford Mustang Mach-E (2021-24) | No | ~66% (Here’s How Much Range These Popular EVs Lose In The Cold) |

| VW ID.4 (US spec) | No | ~63% (Here’s How Much Range These Popular EVs Lose In The Cold) |

Table: Range retention in cold weather. Sources: Recurrent Auto data compiled by InsideEVs (Here’s How Much Range These Popular EVs Lose In The Cold) (Here’s How Much Range These Popular EVs Lose In The Cold). These percentages represent the fraction of normal (mild-weather) range that the vehicles achieve at ~freezing temperature. Higher is better. Teslas with heat pumps (and other EVs that have them, like Hyundai’s) clearly outperform those relying only on resistive heat.

As shown above, Tesla’s newest models (3/Y with heat pump) sustain about 85–87% of their range in the cold, whereas a Mach-E without a heat pump only managed 66% (a 34% drop) (Here’s How Much Range These Popular EVs Lose In The Cold). Volkswagen’s ID.4 (which in the U.S. ships without a heat pump) was even worse at only 63% (Here’s How Much Range These Popular EVs Lose In The Cold). This real-world data reinforces how much energy heat pumps save. The Hyundai Ioniq 5 and Kona EV, which also use heat pumps and extensive waste heat scavenging, achieve mid-80s percent – nearly as good as Tesla. In fact, in one Norwegian winter test, the Hyundai Kona was able to drive 405 km out of its 449 km rated range (91% retention) in –6 °C weather (Hyundai heat pump tech – VASA), thanks in part to its heat pump system. Tesla’s Model Y and 3 have demonstrated similar strong cold-weather performance, often coming in near the top of winter range tests (though Tesla’s optimistic rated ranges mean the percentage drop can appear larger even if the absolute range is still high).

In summary, Tesla’s advanced heat pump and Octovalve design yield substantial efficiency gains over older resistive heating setups: on the order of 10–20% improvement in typical cold conditions, and even more against certain competitors. It allows drivers to use climate control liberally in winter without as severe a range penalty. This technological edge in HVAC efficiency contributes to Tesla’s reputation for having higher real-world range and better energy management in EVs. It’s also pushing other automakers to adopt similar systems to remain competitive in cold-weather markets.

Materials and Components: Compressors, Refrigerant, and Innovation

Implementing this cutting-edge HVAC system required Tesla to innovate not just in circuit design, but also in the choice of materials and components to meet performance and efficiency targets. Let’s look at some of the key hardware elements:

- Electric Compressor: The workhorse of any heat pump is the compressor. Tesla employs a high-voltage electric compressor (likely a scroll or swash-plate type) capable of varying its speed to match heating/cooling demand. Munro’s teardown noted that the Model Y’s compressor is comparable to a “3–4 ton” HVAC compressor (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media) in capacity – meaning it can draw on the order of 5–6 kW of power at full tilt and move a very large volume of refrigerant. This is roughly on par with (or a bit larger than) the A/C compressors in other large EVs and needed to provide strong heating performance (since at COP≈1 in deep cold it effectively becomes a 5 kW heater). The compressor is mounted in the front unit along with the manifolds. Interestingly, Munro pointed out Tesla did not include a noise-dampening shroud or enclosure around the compressor in the Model Y (Inside Tesla’s Octovalve – VASA). This was a cost/weight decision; while it keeps the design simpler, it can result in some audible pump noise. (Many cars have an insulating cover over the compressor to muffle the characteristic hum/whine of the pump.) Musk has mentioned improvements in later models to reduce HVAC noise, potentially by fine-tuning the compressor RPM profiles or adding insulation. Overall, the compressor Tesla uses is state-of-the-art in terms of efficiency – it likely uses an oil separator and advanced refrigerant management to maintain performance even in low temperatures. The ability to modulate its speed allows the system to save energy under partial loads (most of the time it needn’t run full blast).

- Refrigerant (R1234yf): Tesla uses the refrigerant HFO-1234yf in all new models (Tesla Octovalve analysis – E-Mobility Engineering). R1234yf is a more environmentally friendly refrigerant with an ultra-low global warming potential (GWP) of <1, introduced to replace the older R134a (GWP ~1300) in automotive AC systems. It has similar thermodynamic properties to R134a, so performance is comparable, but it is classified as mildly flammable (A2L). Tesla’s system, like all modern cars with R1234yf, is designed with safety in mind – the components (like the refrigerant manifold and seals) are robust, and the refrigerant charge is limited to a small amount. In the Model Y, the refrigerant super-manifold is made of aluminum and was produced with advanced techniques (semi-solid forging, etc.) to ensure it can withstand pressure and temperature cycling (Inside Tesla’s Octovalve – VASA). By integrating the refrigerant paths in a solid manifold block, Tesla reduces the risk of leaks compared to having many separate hoses. The refrigerant loop includes a traditional condenser (front radiator coil) and an evaporator (cabin coil), as well as the chiller (a refrigerant-to-coolant heat exchanger) and a liquid-cooled condenser for heat-pump mode (Inside Tesla’s Octovalve – VASA). The liquid-cooled condenser is essentially another heat exchanger where hot refrigerant can release heat into the coolant loop (which might be feeding the battery or drive unit loop in heating mode). Managing flow through these various exchangers requires careful control via electronic expansion valves – Tesla can selectively direct refrigerant to either the cabin evaporator or the chiller or both, depending on needs. The use of R1234yf does impose some design tweaks (slightly different pressure/temperature characteristics), but clearly Tesla has made it work well. The choice of refrigerant also aligns Tesla with global environmental regulations without sacrificing performance.

- Coolant and Pumps: The Octovalve controls the flow of a water-glycol coolant (an ethylene glycol mixture with corrosion inhibitors) throughout the car (Inside Tesla’s Octovalve – VASA). The coolant is the medium that carries heat to or from the battery pack, motors, power electronics, and cabin heater core. Tesla uses at least two electric coolant pumps to circulate coolant through the loops (Inside Tesla’s Octovalve – VASA). These pumps are variable-speed and computer-controlled. For example, one pump might primarily handle the battery loop and another the drive unit loop, or they can work in tandem to push coolant through the chiller and into the cabin loop as needed. The coolant chosen is a HOAT (Hybrid Organic Acid Technology) glycol, per Tesla’s documentation (Inside Tesla’s Octovalve – VASA) – this is similar to the antifreeze used in many modern cars, which prevents corrosion in mixed metal systems (important since Tesla’s cooling system has aluminum, steel, plastics, etc.). The use of a polymer (nylon) for the coolant manifold also avoids some corrosion concerns and helps reduce weight. The coolant lines are insulated and routed to maximize thermal efficiency – shorter runs and the ability to isolate sections means less heat loss. Notably, Tesla’s battery pack is also insulated and has a heating mat in older models; with the heat pump, the battery can now be warmed via coolant as well. By controlling pump speeds and Octovalve positions, Tesla’s system can ensure, for instance, that coolant flows slowly through the cabin heater core when maximum heat transfer is needed, or bypasses it entirely when not needed. All of this fine-grained control contributes to efficiency and responsiveness (fast warm-up or cool-down times).

- Manifold and Valve Construction: The Octovalve module itself (the rotary valve) is a compact cylindrical part made of plastic and some metal internals. Munro’s CT scan of the Octovalve showed intricate internal channels and seals that line up as the rotor turns (Tesla Octovalve analysis – E-Mobility Engineering). The valve must maintain a tight seal between ports to avoid mixing flows that shouldn’t mix. Tesla’s design uses large diameter seals and a stepper motor with a gearbox to get precise positioning (Tesla Octovalve analysis – E-Mobility Engineering). The coolant manifold (to which the Octovalve mates) is molded from glass-filled nylon and has multiple passages. This material can handle the coolant temperature range and pressure while being lighter than aluminum. The refrigerant manifold is aluminum for strength (since refrigerant pressures can be 10–20 bar). Tesla utilized friction stir welding and brazing to join sections of the aluminum manifold (Inside Tesla’s Octovalve – VASA), ensuring leak-proof connections without the porosity that casting might have. Additionally, they used EDM (electrical discharge machining) to cut small relief features in the manifold, which accommodate thermal expansion and prevent crack initiation during repeated thermal cycles (Inside Tesla’s Octovalve – VASA). These manufacturing techniques are quite advanced for an automotive HVAC component – it shows Tesla treated this like a high-end piece of hardware, akin to aerospace methods, to achieve reliability and performance. By contrast, many other automakers still rely on rubber hoses and crimped fittings that are more failure-prone. The net effect is that Tesla’s system can handle rapid changes in temperature and pressure with minimal degradation over time.

- Auxiliary PTC Heaters: Even though the heat pump does the heavy lifting, Tesla did include small PTC resistive heaters as auxiliaries. According to the patent and analysis, there are 12V PTC heating elements (around 1 kW each) placed likely in the cabin air path (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). These would be used for instant windshield defrost (blowing hot air immediately while the heat pump ramps up) or supplemental heat in extreme cold. They operate on the 12V system (drawn from the high-voltage via DC/DC converter), and because they’re low power, they don’t drastically hurt range but can provide immediate warmth. The presence of these ensures that cabin comfort isn’t compromised in scenarios where the heat pump might need a minute to build up heat. Many heat-pump EVs do similarly include a backup PTC heater (for example, Nissan and Chevy include a resistive heater that kicks in below a certain temperature). Tesla was even able to eliminate the large high-voltage PTC heater entirely – in previous models there was a 6 kW high-voltage heater for cabin air, which is now gone. The COP=1 compressor mode essentially replaces that high-voltage heater (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media), using the compressor as a heater when needed. This is a novel approach in the automotive space (borrowed from commercial HVAC) that Tesla patented and implemented.

- Insulation and Thermal Retention: Tesla paid attention to keeping the system thermally efficient. For instance, components like the chiller and coolant lines are likely insulated to reduce heat leakage. The battery pack in Model Y/3 has a foam insulation layer, helping it retain heat in cold weather (so that if you warm the battery, it stays warm longer, reducing repeat heating). The front radiator has shutters that close when not actively cooling, which not only reduces drag but also prevents cold air from over-cooling the coolant loops and cabin heater when heat is desired (Inside Tesla’s Octovalve – VASA). By keeping the engine bay more thermally sealed when needed, Tesla’s system can retain heat better than an open-grille design. One critique Munro had was the lack of an insulating cover on the compressor, which could also mean some compressor heat is lost to the environment or it runs a bit noisier (Inside Tesla’s Octovalve – VASA). It’s possible Tesla determined the impact on overall efficiency was minor, or they prioritized ease of service. In any case, any future improvements might include more acoustic/thermal enclosures if needed.

In terms of materials summary: plastics where possible, metal where necessary is the mantra. The result is a relatively lightweight assembly that still handles the demands of pressure and temperature. The entire Octovalve heat pump module (manifolds + compressor) sits neatly at the front of the car, taking up space that in an ICE vehicle would be partly occupied by an engine. Tesla even maintained a front trunk (frunk) in Model Y by keeping this module compact and low – roughly a large briefcase size, as noted (Tesla Octovalve analysis – E-Mobility Engineering). Competing designs often require more space or end up reducing storage. (As we’ll see, Ford had to shrink the Mach-E’s frunk to add a heat pump later.)

To conclude this section, Tesla’s choice of components like the high-efficiency electric compressor, the eco-friendly R1234yf refrigerant, and the custom-engineered manifolds showcase the cutting-edge engineering behind the HVAC system. It’s not off-the-shelf parts slapped together; Tesla custom-designed many parts to serve this integrated purpose. The Octovalve assembly itself is a testament to clever design and manufacturing, combining injection molding, CNC machining, and welding techniques to create something new in the automotive world. This holistic approach to materials and components is a big part of why the system performs so well and reliably despite its complexity on paper.

Comparing Tesla’s HVAC to Legacy and Competing Systems

Tesla’s Octovalve heat pump system represents a new paradigm in vehicle thermal management, and it’s interesting to compare it against both the legacy automotive HVAC approach and the systems in other modern EVs.

Legacy ICE HVAC vs Tesla’s System: In a traditional gasoline car, you have a very simple thermal setup: an engine produces waste heat which is used to warm the cabin (via engine coolant flowing through a heater core), and an AC compressor (belt-driven) cools the cabin when needed. There is typically no active cooling for the engine beyond a radiator and fan, and certainly no need to heat the engine (quite the opposite, engines produce too much heat). Battery conditioning is nonexistent (in non-hybrid ICE vehicles). So while ICE cars have a form of “heat pump” (the AC) and an abundant heat source (the engine) for heat, they lack any integration – waste heat can’t be repurposed beyond cabin heating, and there’s no concept of moving heat into various subsystems.

Early EVs and hybrids, taking cues from ICE designs, often mimicked this separate-loop approach: multiple independent cooling loops for battery, motor, etc., and cabin heating via resistive heaters. For instance, the Chevy Bolt EV has one loop for battery (with its own electric coolant heater for winter and chiller tied into the AC for cooling the battery) and a separate loop for cabin HVAC with its own PTC heater and AC evaporator. These systems work, but they involve lots of redundant components – multiple pumps, multiple radiators or heat exchangers, many hoses and valves. Munro’s teardown of the Model Y highlighted that conventional EVs like the Bolt, Nissan Leaf, Jaguar I-Pace, Audi e-tron, etc., had “hundreds” of parts in their thermal systems, whereas Tesla’s integrated approach cut that down drastically (Tesla Octovalve analysis – E-Mobility Engineering). Fewer parts not only mean lower manufacturing cost and weight, but also fewer potential failure points.

Another legacy approach aspect is that most earlier EVs used resistive heating for the cabin, which as discussed is a range killer in cold weather. For example, the Nissan Leaf (first generation) had only resistive heaters and could lose 30–40% of its range in winter due to heater usage. Some later Leaf models introduced a small heat pump for the cabin (Leaf SV/SL trims had an optional heat pump HVAC around 2013+), which improved things slightly but it was not as extensive as Tesla’s system (the Leaf’s heat pump didn’t heat the battery, it was only for cabin). The Jaguar I-Pace initially had only resistive heat, and later added a heat pump as an option. The Audi e-tron Quattro SUV launched with a standard heat pump for cabin heating, but still had a fairly complex arrangement of coolant loops for its drivetrain (not as consolidated as Tesla’s). These legacy systems typically treat the battery thermal management as a separate domain – for instance, they might use a secondary refrigerant-to-coolant chiller to cool the battery in summer, but not use the battery as a heat source for cabin heating in winter. That’s a key difference: Tesla blurs the lines between subsystems, whereas others historically kept them isolated for simplicity.

Competitor EV Platforms (Ford, Hyundai, VW, etc.): In recent years, other automakers have started to implement more integrated thermal management, though approaches vary:

- Ford Mustang Mach-E: The Mach-E, launched in 2021, initially did not include a heat pump for cabin heating – it relied on resistive PTC heaters. Ford likely prioritized getting the car out quickly and kept the HVAC simpler (and indeed, Mach-E owners in cold climates noticed significant range drops). Data above shows the Mach-E retaining only ~66% of its range at freezing, one of the poorer performers (Here’s How Much Range These Popular EVs Lose In The Cold). Acknowledging this shortcoming, Ford announced that the 2025 Mach-E will include a standard heat pump system for the first time (2025 Mustang Mach-E Adds Sportier Looks, Auto Lane Changes …) (2025 Mustang Mach-E drops with heatpump, smaller frunk, $36K price, more | Electrek). However, adding this after the fact came with a cost: the existing design didn’t allocate space for a large integrated HVAC module, so Ford had to shrink the front trunk volume to accommodate the new heat pump hardware (2025 Mustang Mach-E drops with heatpump, smaller frunk, $36K price, more | Electrek). Ford engineers literally had to take space from the frunk because the heat pump couldn’t be packaged under the original hood without doing so (2025 Mustang Mach-E drops with heatpump, smaller frunk, $36K price, more | Electrek). This contrasts with Tesla’s design, which from the start was built around the Octovalve module while still preserving a frunk. The Mach-E’s new heat pump will likely improve its winter efficiency greatly (possibly bringing it in line with ~80% range retention or more, if integrated to also help battery heating). Ford’s implementation, according to their statements, aims to integrate battery and cabin thermal management similar to Tesla (2025 Mustang Mach-E drops with heatpump, smaller frunk, $36K price, more | Electrek), though details are sparse. Nonetheless, it’s telling that Ford had to follow Tesla’s lead due to customer demand – cold-weather range was a pain point. The Mach-E example highlights how packaging and integration are crucial: Tesla’s highly integrated unit was an upfront investment that paid off in efficiency without compromising cargo space, whereas Ford is retrofitting that capability at the cost of some practicality.

- Hyundai/Kia (Ioniq 5, Kona, EV6): Hyundai Motor Group was actually an early pioneer of EV heat pump technology. The Kia Soul EV in 2014 had a heat pump system, and Hyundai/Kia have continually improved it (Hyundai heat pump tech – VASA) (Hyundai heat pump tech – VASA). Their latest EVs like the Hyundai Ioniq 5 and Kia EV6 come standard (in many markets) with heat pump-based climate control. Hyundai’s system is conceptually similar to Tesla’s in that it scavenges waste heat from multiple sources – they explicitly stated their heat pump can capture heat from the drive motor, power electronics, onboard charger, and the battery itself to reuse for cabin heating (Hyundai heat pump tech – VASA) (Hyundai heat pump tech – VASA). In a Norwegian cold range test, as noted, the Hyundai Kona Electric outperformed many EVs by retaining 91% of its range in -6 °C weather (Hyundai heat pump tech – VASA). This indicates Hyundai’s approach is very effective (Kona is a smaller vehicle, but still, the efficiency was notable). The difference is largely in implementation: Hyundai’s systems before were more like a collection of separate loops with clever valving (they didn’t have an “octovalve” per se, but they had multiple solenoid valves to route refrigerant among an array of components). The new E-GMP platform (Ioniq 5/6, EV6, EV9) presumably has a central coolant distribution unit as well, though details are scarce publicly. Hyundai did publicize that they test their heat pumps in -35 °C conditions in Sweden to ensure operation in the coldest environments (Hyundai heat pump tech – VASA). One could say Hyundai matched a lot of Tesla’s tricks (and in fact Tesla’s patent mentions Kia/Hyundai systems coming close in some methods (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media) (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media)). Both use waste motor heat, both can heat the battery (Hyundai EVs have battery heaters and presumably can route heat pump warmth to the pack). Where Tesla might still have an edge is the integration density – the Octovalve block replacing many discrete parts. Also, Tesla’s software tuning and user experience (automatic preconditioning for Supercharging, etc.) is very refined. But Hyundai deserves credit for being one of the first to prove heat pumps in EVs can greatly reduce winter range loss. In practice, a Hyundai Ioniq 5 with heat pump retains ~85% of range in winter (as per Recurrent data) (Here’s How Much Range These Popular EVs Lose In The Cold), virtually on par with Tesla’s 86%. So in terms of outcomes, Tesla and Hyundai are quite comparable, suggesting the industry as a whole is converging on these solutions.

- Volkswagen (ID.4, ID.3, Audi, etc.): VW’s approach has been somewhat inconsistent. The VW ID.4 in Europe could be optioned with a heat pump, but in the U.S. the initial models did not have that option (likely for cost reasons, as an entry-oriented EV). The result, as shown, was that ID.4 owners without heat pumps saw large range losses – only ~63% of range retained at freezing for US ID.4 (no heat pump) (Here’s How Much Range These Popular EVs Lose In The Cold). VW did offer the heat pump as a ~$1,500 option in Canada for a short time but then discontinued it due to complaints (Here’s How Much Range These Popular EVs Lose In The Cold). Some reports suggested that ID.4’s heat pump wasn’t delivering as much benefit as expected for the cost, possibly due to software issues or a less advanced design. Audi’s e-tron SUV, on the other hand, comes standard with a heat pump and has a pretty elaborate thermal management (including cooling for the battery and motors). The Audi e-tron was noted to retain ~87% of range in cold (Here’s How Much Range These Popular EVs Lose In The Cold), indicating its system works well. However, Audi’s solution didn’t achieve the level of integration Tesla did in terms of parts count – Munro pointed out that even the e-tron (which he tore down) had far more hoses and components. One difference is that Audi (and VW to an extent) prioritized comfort over efficiency – the e-tron will use resistive heat in conjunction with the heat pump to ensure the cabin gets warm very quickly, possibly not maximizing efficiency at all times. Tesla tends to lean more on the heat pump, doing things like the “local heating loop” Musk described to avoid needing resistive heat (Tesla’s Octovalve Enabled A Staggering 10% Increase In Range For The Model Y – CleanTechnica). VW’s discontinuation of the ID.4 heat pump option in North America, and plans to perhaps reintroduce improved designs, shows that not all heat pump implementations are equal. It’s not just having a heat pump, but how you use it. Tesla’s software and control algorithms (15 distinct modes, remember) likely extract more benefit from the hardware than a simpler control strategy would.

- General Motors (Bolt, Lyriq, etc.): The Chevy Bolt EV stuck with a pure resistive heating system (no heat pump) through its life, and as a result it suffers big range losses in winter (as AAA tests showed, up to 40-50%). GM’s newer EVs like the Cadillac Lyriq and upcoming models on the Ultium platform do have heat pump-based thermal systems. However, interestingly, early data from Recurrent suggests the Lyriq and Chevy Equinox EV are not performing as well as expected – retaining only ~72-74% in cold despite having heat pumps (Here’s How Much Range These Popular EVs Lose In The Cold). This could be due to software calibration, or the vehicles being heavier and requiring more energy for heating. It highlights that engineering a good heat pump system involves balancing many factors: system size, how it’s integrated, and control logic. Tesla’s years of experience and emphasis on efficiency appear to give it an advantage in achieving near-optimal results.

In broad terms, Tesla’s competitive edge with the Octovalve system lies in its integration and control sophistication. Many other EVs now have the basic hardware (heat pump, valves, etc.), but Tesla’s solution was early to unify everything – battery, drive units, cabin – with one central “thermal brain.” This not only yields efficiency, but also simplifies assembly and maintenance. Fewer separate subsystems mean less weight and cost. When Sandy Munro reviewed Tesla’s thermal system against others, he lauded that it was unlike anything from a “normal OEM” (Inside Tesla’s Octovalve – VASA), and that it embodied Tesla’s characteristic approach of treating the car like a computer or integrated system rather than a sum of discrete parts.

One can also compare performance metrics like heating capacity and response times. Tesla doesn’t publish explicit heater kW specs, but we know the Model Y heat pump can deliver around 5–7 kW of heat output (at least) since it can replace a 6 kW resistive heater (Tesla Model Y Heat Pump Details Infrequently Discussed By The Media). Competitors with heat pumps have similar capacities; for example, Audi e-tron’s heat pump is rated around 3 kW heat output at -10°C and up to ~10 kW at mild temps (these numbers gleaned from user forums). The Mach-E’s new heat pump is expected to have on the order of 5 kW heating as well. Where Tesla shines is the ability to also draw on supplemental heat sources (if the motor can add 3–4 kW of waste heat, that effectively increases total heating capacity without extra drain). So the occupants feel warm just as quickly as in any other car – Tesla’s can heat the cabin fast by briefly running the auxiliary heaters and using the motor trick, achieving near-immediate hot air. Some early EV heat pumps had a reputation for slower heating (because pumping heat from freezing air can be sluggish), but Tesla largely solved that with the local loop and auxiliary heat.

From an energy consumption perspective, Tesla’s system and the best of its competitors (Hyundai, etc.) are in a different league than legacy systems. AAA tests a few years ago found a typical EV at 20°F could lose 41% of its range with the heater on (Study: How Much Heat Pumps Boost EV Range). Now, with heat pumps, many EVs lose perhaps 10-20%. It’s a transformative improvement. Tesla essentially made heat pumps standard across its lineup around 2020-2021 (Model Y from launch, then Model 3 refresh in late 2020, and the new S/X in 2021). This put pressure on others: Nissan’s new Ariya SUV has a heat pump standard (it retains ~83% range in cold, per data (Here’s How Much Range These Popular EVs Lose In The Cold)), Ford as mentioned is adding it, GM is adding it, etc.

In terms of industry leadership, Tesla’s Octovalve system arguably set a benchmark that others are now chasing. The integration of what normally would be separate cooling circuits into one combined circuit was a bold engineering move. It reflects a mindset of “whole car optimization” that Tesla is known for. Instead of having a battery thermal management supplier and an HVAC supplier provide separate modules, Tesla designed a unified system in-house. This is similar to how they approached electronics (creating central ‘Tesla OS’ for the car rather than dozens of independent ECUs). The payoff is clear in efficiency and even cost (fewer parts, though some parts are complex). Traditional automakers are beginning to move in this direction, but many are a step behind. For example, the Rivian R1T/R1S trucks launched without a heat pump (they used resistive heating and saw only ~81% range retention) (Here’s How Much Range These Popular EVs Lose In The Cold), which is surprising for a modern EV – likely a decision to simplify first production. Rivian has stated they will incorporate heat pumps in future updates. It goes to show that Tesla’s foresight in this area gave them an edge that others are now working to close.

Finally, from a consumer perspective, what Tesla has achieved is making the EV driving experience more consistent. Early EV adopters often had to accept that “range may drop dramatically in winter due to heater use.” Tesla owners now find that, while there is still some drop (physics can’t be defied entirely – cold batteries hold less energy and cold air is denser causing more drag), the cabin heating itself is far less of a culprit than it used to be. This narrows the gap between EVs and ICE cars (which also see some MPG drop in winter, though for different reasons). Competing EVs that have followed suit also deliver improved winter performance, which is great for EV adoption generally. As more brands implement integrated heat pump systems, the industry as a whole benefits from the efficiency gains. Tesla’s Octovalve was one of the catalysts for this shift.

Conclusion

Tesla’s advanced heat pump and Octovalve-based HVAC system represents a significant engineering leap in automotive thermal management. By reimagining how to distribute heat and cold across the cabin, battery, and powertrain, Tesla created a single, intelligent thermal network that maximizes efficiency and performance. The Octovalve manifold is the keystone – an elegant hardware solution that replaces dozens of valves and interfaces with one centrally controlled unit. This enables Tesla’s vehicles to smartly scavenge and redirect heat where it’s needed, whether warming the cabin with waste motor heat, cooling the battery with surplus AC capacity, or even storing solar heat in the battery for later use. The result is an HVAC system that not only keeps occupants comfortable across extreme climates, but also minimizes energy consumption, preserving precious battery range.

The data from real-world use and third-party tests make it clear that Tesla’s efforts paid off – their latest models suffer far less range degradation in cold weather compared to earlier EVs or competitors that lack such integrated heat pumps. Achieving this required innovation at multiple levels: novel control logic (15+ operating modes), custom manifolds and valves to integrate coolant and refrigerant loops, use of cutting-edge refrigerant and materials, and a holistic vehicle-level approach to thermal design. Tesla effectively treated thermal management as a first-class citizen in the vehicle’s design, on par with the battery and powertrain, rather than an afterthought.

As we’ve seen, other manufacturers are now following suit – adding heat pumps and trying to connect systems together – validating Tesla’s approach. Owners of EVs like the Mach-E and ID.4 are eagerly anticipating the kind of improvements that Tesla owners have already experienced. In the relentless pursuit of efficiency, Tesla’s Octovalve system is a prime example of the company’s ability to rethink traditional automotive systems from the ground up. It showcases how engineering innovation can yield tangible customer benefits (like more winter range and faster heating) while also advancing the state of the art.

Moving forward, one can expect continued refinement in this domain. Perhaps we’ll see even more integration (e.g., incorporating passenger seat occupancy sensors to target heating, or integrating the AC with future Tesla solar roofs on the car). Tesla has even hinted at leveraging their vehicle HVAC expertise to develop super-efficient home HVAC systems in the future (Tesla’s Octovalve Enabled A Staggering 10% Increase In Range For The Model Y – CleanTechnica). But within their cars, the Octovalve heat pump is already a standout feature that gives Tesla an edge in efficiency and technology.

In summary, Tesla’s most advanced cabin HVAC and heat pump system – with the Octovalve at its heart – exemplifies state-of-the-art thermal engineering in service of electric vehicle performance. It ingeniously manages the thermal flows between the cabin, battery, and drivetrain to keep all aspects of the vehicle in optimal condition, all while using as little energy as possible. This level of integration and efficiency is a key enabler of Tesla’s range and user experience advantages, and it’s pushing the whole EV industry forward as rivals adopt similar strategies. Tesla has effectively turned the humble act of heating and cooling into a high-tech dance of thermodynamics – one that happens behind the scenes, to the benefit of everyone riding inside.

Leave a comment